Aluminium Foil for Transformer

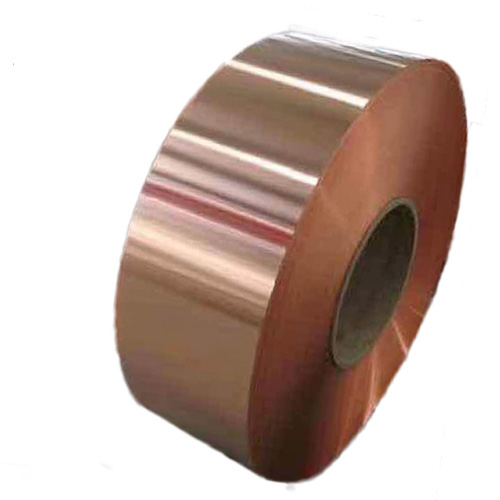

The aluminium foil used in transformers are made from high-quality, pure aluminum with a minimum purity of 99.5%, ensuring excellent electrical conductivity.

Detailed Technical Requirements for Aluminium Foil Used in Transformers:

1. Material Specification:

– The aluminum foil used in transformers should be made from high-quality, pure aluminum with a minimum purity of 99%, ensuring excellent electrical conductivity.

– The thickness of the aluminium strip should be specified according to the design requirements of the transformer. Commonly used thicknesses range from 0.2 mm to 3 mm.

2. Surface Finish:

– The surface finish of the aluminium foil should be clean, smooth, and free from scratches, oil, dirt, or any other contaminants that may affect its performance.

– Any surface treatment, such as anodizing or coating, should be carried out as per the customer’s specifications.

3. Dimensional Tolerance:

– The width, length, and thickness of the aluminium foil should conform to the specified dimensional tolerance limits. The tolerances should be determined based on the transformer design requirements and industry standards.

4. Mechanical Properties:

– The aluminum foil should possess good mechanical properties to withstand transformer manufacturing processes, including bending, stamping, and winding.

– The strip should have sufficient tensile strength and elongation to avoid deformation or breakage during these processes.

5. Electrical Conductivity:

– The electrical conductivity of the aluminium foil is crucial for efficient energy transfer in transformers. It should have a high electrical conductivity, typically exceeding 58% IACS (International Standard).

6. Chemical Composition:

– The chemical composition of the aluminium s should be within the specified limits to ensure its electrical and mechanical properties. Common impurity limits include iron (Fe), copper (Cu), silicon (Si), zinc (Zn), manganese (Mn), and magnesium (Mg).

7. Reliability and Durability:

– The aluminum strip should exhibit excellent resistance to corrosion, oxidation, and aging, ensuring long-term reliability and durability in transformer applications.

– It should also have good thermal stability to withstand the operating temperatures encountered in transformers.

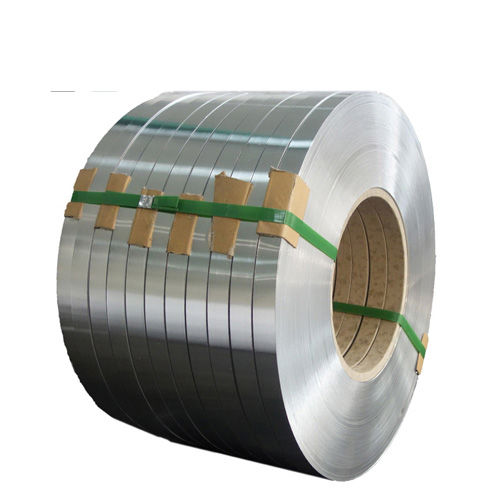

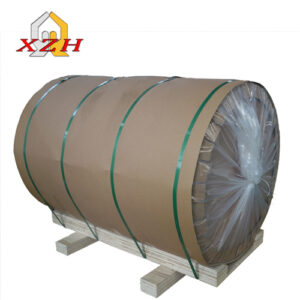

8. Packaging and Handling:

– The aluminum strip should be packaged in a way that prevents damage during transportation and storage. Suitable packaging materials, such as wooden crates or plastic wraps, should be used.

– Proper handling instructions should be provided to avoid any bending, scratching, or other physical damage that may affect the strip’s performance.

Please note that the above technical requirements may vary depending on the specific transformer design and industry standards. It is important to consult the transformer manufacturer or refer to relevant specifications for precise technical requirements in each case.

The conductivity of this aluminum foil is excellent, can efficiently transmit the current, to ensure that the transformer in the operation of the process of loss is very low, enhance the efficiency of energy use, for energy saving and emission reduction has made an important contribution to the cause. Moreover, its flexibility is very good, in the processing and installation process can easily adapt to a variety of complex shapes and sizes, greatly improving production efficiency and equipment reliability.

In addition, the corrosion resistance of our aluminum foil is also quite excellent, and it can work stably for a long time in a variety of harsh environments, which prolongs the service life of the transformer and reduces the maintenance cost and replacement frequency.

Its smooth and flat surface can effectively reduce eddy current loss, further optimize the performance of the transformer, so that it can still maintain high efficiency and stability under the operating conditions of high frequency and high current.

In conclusion, aluminum foil for transformers is an indispensable and high-quality material in the electrical field, providing a solid and efficient guarantee for power transmission and conversion, and is the real behind-the-scenes hero in modern power systems!

More info about electrical plant ,Visit More Info

Find more Chinese Aluminum Price visit:https://www.ccmn.cn/